Certified EVA PU Foam Wood Engraving Mill Cutting CNC Router Machine with Rotary

Basic Info

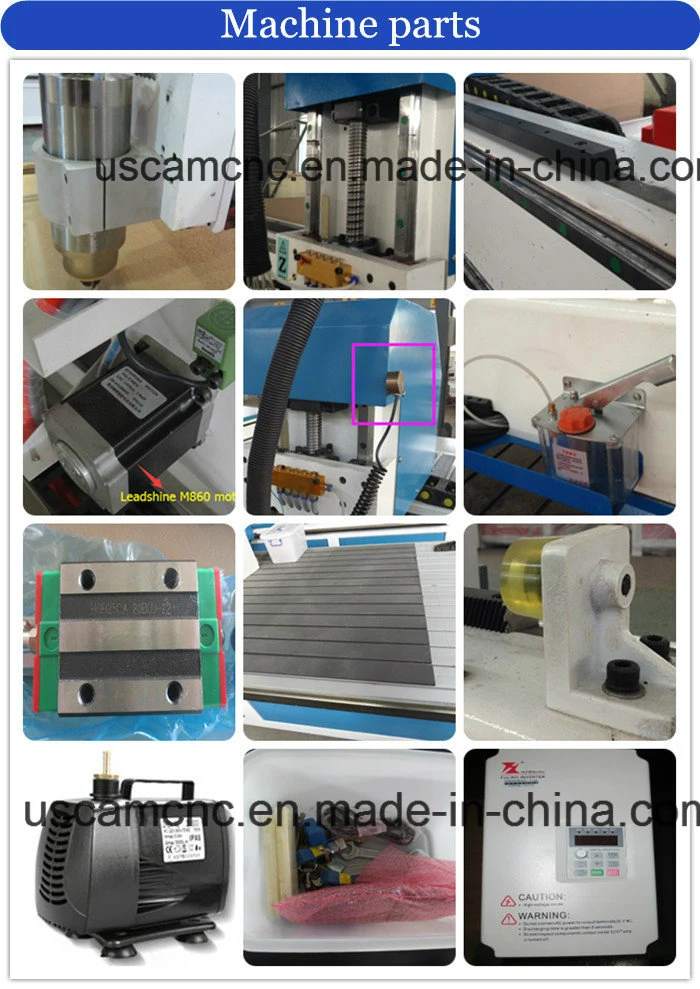

| Working Area | 1300*2500*200mm |

| Spindle | 3.0 Kw Water Cooling Spindle |

| Table | T-Slot Table/Vacuum Table |

| Rail | Taiwan Hiwin Square Rail |

| Inverter | Fuling Inverter |

| Motor | Stepper Motor |

| Driver | Leadshine M860 Driver |

| Additional Parts | Water Tank and Water Pump |

| Transmission | X, Y Gear Transmission, Z-Axis Taiwan Tbi Ball SCR |

| Type | CNC Router |

| Feature | Wood Router |

| Transport Package | Strong Plywood Cse |

| Trademark | USCAM |

| Origin | China |

| HS Code | 8479899990 |

| Production Capacity | 500sets/Month |

Product Description

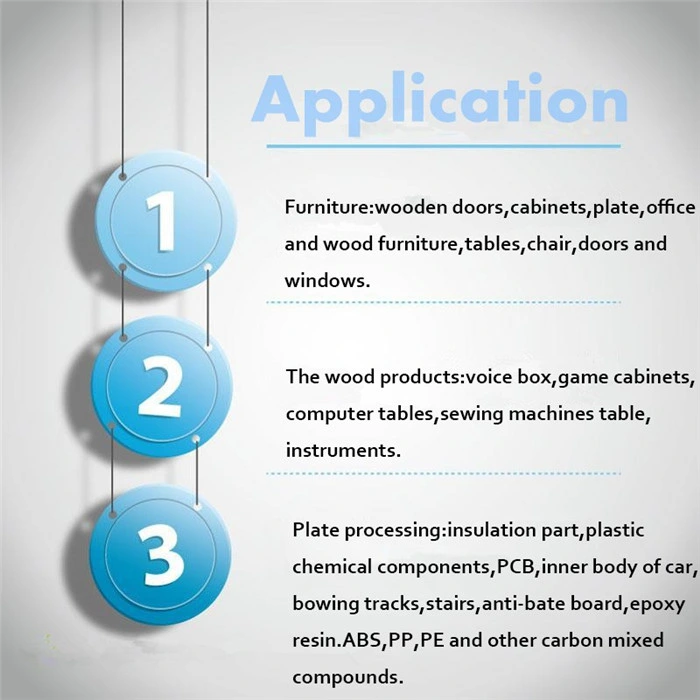

Certified EVA PU Foam Wood engraving Mill Cutting cnc router machine with rotaryFoam, dvertising signs, logo making, acrylic cutting, PP/PE/ABS/PVC/PC Board Cutting engaving, making of various materials, decorative products, and wood relief engraving or cutting,like wood window processing, wood table, chairs,wood doors, Woodenworking Industry , 3D Wave Board Provessing , Cupboard Doors, Crafts Wooden Doors ,Unpainting Door ,Screen ,Crafts Windows ,Milling and Endraving On The Furniture,etc

1) Working Area: 1300x2500x500mm2) DSP control system/Nc-studio control system3) 3.0kw water cooling spindle(optional)4) Leadahine drivers and stepper motors5) Fuling inverter6) T-slot table/Vacuum table7) Original Artcam software8) Standard body frame9) Rack and gear transmission10) Taiwan HIWIN Linear square rails11) Taiwan TBI Ball Screw for Z Structure12) Oil injection system13) One set cutting tools14) Color optional15) Dust collectorParameter of :

| MODEL | USM1325 Standard body frame |

| X Y Z Working area | 1300*2500*500 mm |

| Table | T-slot table/Vacuum table |

| Frame | Steel square tube |

| Inverter | Fuling Inverter |

| Spindle | 3.0kw water cooling spindle |

| Motor and rive(STEPPER) | Leadshine driver and stepper motor |

| Switch | Omron |

| Electronic component | Scnieder |

| X Y structure | Taiwan HIWIN square rail linear &rack pinion drive |

| Z sructure | Taiwan HIWIN square rail &TBI ball screw |

| Maximum rapid travel rate | 50000mm more min… |

| Maximum working speed | 30000mm more min… |

| Operating system | DSP controller/Nc-studio system |

| Software | Artcam, type3 |

| Spindle speed | 24000RPM |

| More configuration | Tool sensor,transformer,filter,flash |

| APLICATION | Wood 3d engraving,MDF,HDF,ACP, acrylic; Stone, aluminium with water tank and water pump |

Features of wood dorr cnc router machine for woodworking

1.Welded steel tube structure as a whole with vibration Temper aging treatment ensures no deformation for long time.Cast iron Gantry, the structure is strong and stable.2. Transverse aluminum alloy T slot working table, better for materials fixing.3. Large power 3.0kw water cooling spindle which is with stable performance, lower noise, powerful and high torque, matched with high-performance frequency inverter.4. Imported Hiwin, Taiwan Linear square guide rail with ball bearing slide block which ensure high weight capacity, high precision, smooth and steady running. Adopt imported precision ball screws, tools feeded with more accuracy.5. Helical gears pinion and rack transmission for X and Y axis, higher running speed and efficiency, saving cost. Z- axis with precision ball screw, high precision and more durable.6. China famous stepper motor and driver for XYZ-axis, high precision, fast speed and more stable, dual motor Driven Y axis with traveling speed up to more than 25000mm/min.7. DSP A11(RichAuto) offline control system with USB interface which is completely off from Computer. More Humanizeddesign with Simple and Convenient Handle type operation.With per-calculation rule, fully excavating potentialities of motors. Enable high processing speed, synchronization of Curve and straight line, more perfect curve working and Spindle start up and stop automatically.8. Dust collector, helping to suck dust, milling dust,keeping machine cleaning.

9. 4th axis rotary axis, diameter 80~200mm, length 80~2000mm, reduction gear transmission, ensure the cylinder processing precision.

10. Semi-auto lubrication system more convenient for maintenance.

11.Auto tool calibration, more convenient for each time Z-axis 0 point setting.

12. Favorable compatibility with various CAM softwares such as Type3/Artcam/Mastercam/Caxa. With intelligent over limit protection function which can stop the mechanical collision due to unproper size given to the design.

13. With the function of Break-point memory ,power failure resuming and automatic home/orgin correction function, effectively ensure long time working precision.

After sale Service

# 18 months guarantee of the whole machine, we will provide the consumable parts at an agency price when you need replacement.

# Main parts(excluding the consumables) shall be changed free of charge if there is any problem during the warranty period.

# Software is on update for free whole life.# Our engineer could support you technology to your country if necessary.# Our enginner could service on weekend even on vacation.# Our engineer could train you in our factory for free.# Our engineer could service you 24 hours online by Skype, yahoo, msn, QQ, or by cellphone.# English manual and CD video for machine using and maintaining will send to you with the machine.