New Cheap Mini Engraving Metal Machine 6090 Mould CNC Router

Basic Info

| Model NO. | 6090 |

| Carving Material | Stainless Steel |

| Controlling Mode | CNC |

| Main Axle Rotational Speed | ≤24000rpm |

| Milling Cutter Diameter | 3.1 |

| Feeding Height | 200mm |

| Certification | CE |

| Warranty | 24 Months |

| Customized | Customized |

| Condition | New |

| Machine Bed | The Whole Cast Iron Bed, Heavy-Duty |

| Spindle | 3kw Constant Water Cooling Spindle |

| Inverter | 3.7kw Taiwan Delta Inverter |

| Motor and Drive | 750W Yaskawa Servo Motor and Drives |

| Transmission | Taiwan Tbi Ball Screw |

| Guide Rails | Taiwan Hiwin Square Rails |

| Control System | Tk100 / Nk280 |

| Software | Artcam |

| Transport Package | Plywood |

| Specification | 600*600*200(mm) |

| Trademark | APEXCNC |

| Origin | Shandong |

| HS Code | 8465990000 |

| Production Capacity | 100 Pieces/Month |

Product Description

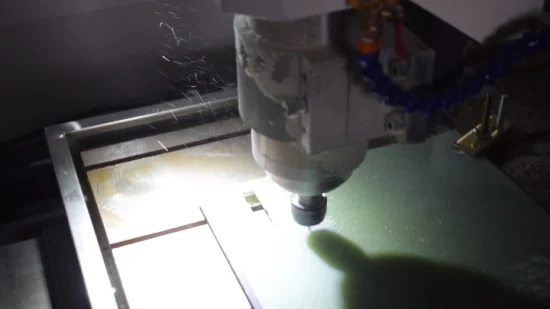

New Cheap Mini Engraving Metal Machine 6090 Mould CNC Router

Product Description

Features:

1.Machine frame with linear guides in an extra-wide configuration.

2.Robust construction for efficient machining.

3.High-precision preloaded ball screws on all 3 axis.

4.Easy accessibility of work table for easy setup and tooling

5.Enclosed work space ensures safe and contamination-free work.

6.Different Operating system as optional: NCstudio, RichAuto, Mach3 Syntec, Siemens, Fanuc.

Technical Data:

| Standard Configuration | |

| Model & Name | APEX6060 |

| Brand | APEXCNC |

| Working Area | 600*600*200(mm) |

| Control system | TK100 control system |

| Spindle | 3.0KW water cooling spindle |

| Motor and drivers | Japan yaskawa servo motor and drivers |

| Rail guide | Taiwan 25 HIWIN square rails |

| Ball Screw | Taiwan TBI grinding ball screw |

| Inverter | Fuling inverter |

| Electronic components | France Schneider electronic components |

| Software | Artcam software |

| Limit switch | Japan Omron limit switch |

| Working Dictate | G-code |

| Water cooling system | Included |

| Technical Parameter | |

| Working area | 600*600*200mm |

| Spindle power | 3.0KW water cooling spindle |

| Spindle speed | 24000RPM |

| Working Accuracy (mm) | ≤0.01mm |

| X,Y,Z Traveling Positioning Accuracy (mm) | ≤0.01mm |

| Max. Idling Speed | 60m/min |

| Max. Working speed | 40m/min |

| Commend Code | G Code |

| Diameter of Cutter | φ3.175-φ12.7 |

| Cooling Mode | Water-cooling |

| Working voltage | 380V 3P 50HZ |

| Interface | USB |

| N.W./G.W. | 700kg/800kg |

| Package size | Package size |

Metal mould making machine application:

Can be used for advertisement engraving, advertisemet cutting, stone processing, Cutting and AL molding, mold manufacturing, wood processing, craft manufacturing, light box cutting, building mold cutting, indoor decoration cutting, light equipment mold processing, sign and mark manufacturing, acrylic board processing, as well as stamp cutting and PCB cutting.

Company ProfileJinan Apex Machinery Equipment is a comprehensive enterprise who is devoted to manufacturing cnc router, laser engraving machine, laser marking machine, plasma cutting machine, stone carving machine.

All products have to pass strict inspection before delivery, and applied the CE, ISO, certificate if the clients must need. Factory covers about 3000 square meters, including R&D center. It has about 300 staffs, 10 engineering experts and 18 technical engineers included, After years of continuous efforts and clients supporting till nowadays, it has developed a working system model of design, production, trade one stop service. The new and existing customers are spreading throughout the South America,Middle East, Southeast Asia, Africa, Europe and other Counties and places.

Welcome friends world widely come to visit and expect further continuous support please.

1. Strong water resit bottom in plywood.

2. Metal laser cutting machine parts with separated plywood case.

3. Corner protect by foam and fixed by protective film.

4. All covered by strong and hard protective film.

5. Vacuum packing.

6. Inside steel frame protector.

7. Plywood packing and steel strip outside fixed the box.

8. Finishing packing by normal container or frame container.

Q1.How can i get the machine?

CIF:Almost finish production →order shipment and confirm shipping date→delivery machine to portof loading→declare at customs→shipping→delivery to port of destinationFOB:Almost Finish production→tell us your shipping agent contacts and confirm shipping date→delivery machine to port of loading→declare at customs→shipping→delivery to port of destinationDDP:Almost finish production →order shipment and confirm shipping date→delivery machine to port of loading→declare at customs→shipping→delivery to port of destination-clearance-delivery machine to your placeQ2.Why choose us?We provide you a solution and not just a machine.Well configured machine using hardware that makes the machine efficient, accurate, and reliable.Feel Confident when buy from a CNC company that has expert staffs with over 10 years of CNC building experience.Get the support that you deserve from our confident well trained staff members.iGolden prides itself in having the patience and the ability to provide knowledge and service. Q3. How to choose the most suitable machine?Kindly let us know the following details:1.What is your Max.working area?2.What material will you work on?3.Do you mainly engrave or cut? If cut,What is your Max.cutting thickness?4.You also can send your product samples to us.According to your sample,we will recommend the best suitable machine for you