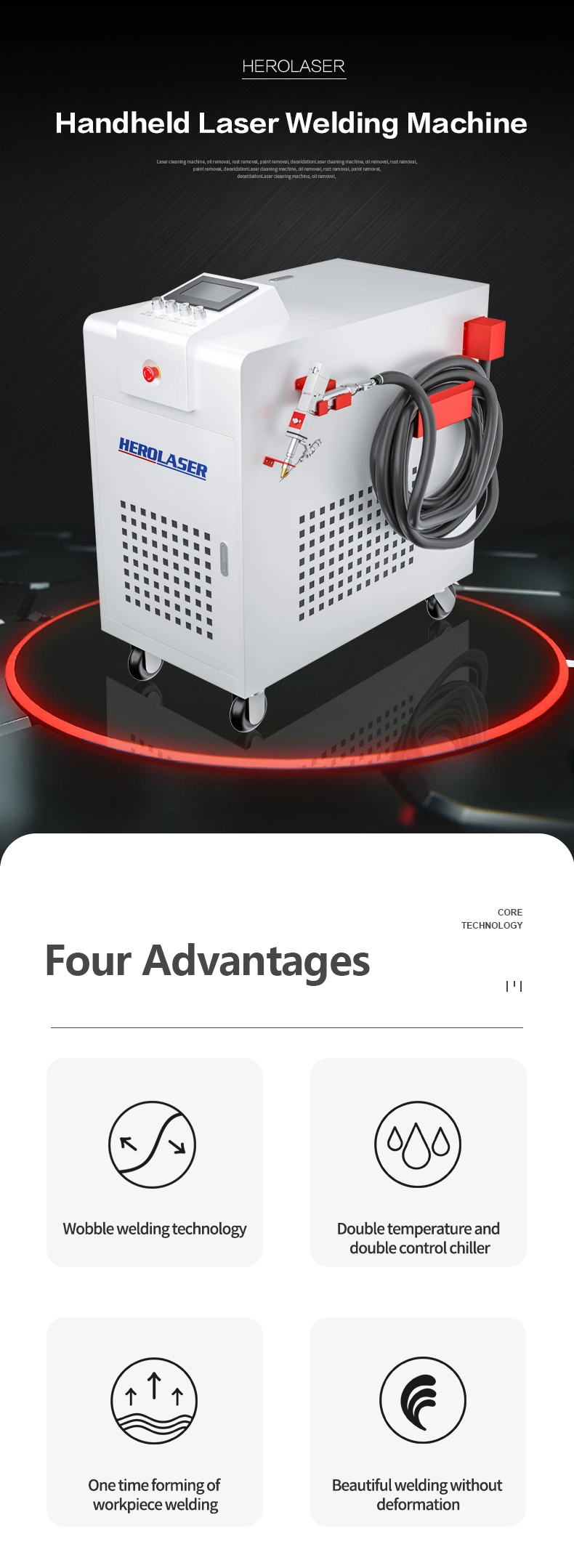

1000W 1500W 2000W 3000W Portable Handheld Mini Fiber Laser Welding Machine for Metal Stainless Steel

Basic Info

| After-sales Service | Free Use of Training and Maintenance |

| Warranty | 2years |

| Application | Electronic Industry, Automotive Industry, Metals Processing |

| Technical Class | Pulse Laser |

| Control | Manual |

| Power Density | Deep Fusion Welding |

| Laser Classification | Optical Fiber Laser |

| Type | Portable Welding Machine |

| Transport Package | Wooden Box |

| Specification | 320kg |

| Trademark | Herolaser |

| Origin | China |

| Production Capacity | 500 Pieces/Month |

Product Description

Water-cooled handheld laser welding machine

Most sales in the market are dominated by water-cooled hand-held welding. Water-cooled hand-held welding uses water as thecooling medium. Our company sells water-cooled welding machines with different powers such as1000W, 1500W, 2000W, 3000W,etc. And mini hand-held welding focuses on three models: 1000W and1500W Water-cooled handheld welding machine features:built-in dual-temperature dual-control industrial chiller, constant temperature regulation and heat dissipation, to ensure the heatdissipation of the core optical circuit components. With fiber laser, stable and efficient.

| Items | Parameter |

| Equipment Name | Handheld fiber laser welding machine |

| Laser Power | 1000W,1500W |

| Laser Wavelength | 1070 NM |

| Fiber Length | Standard 10M Maximum 15M |

| Work Way | Continuously modulated |

| Water Chiller | Industrial thermostatic water tank |

| Working Environment Temperature | 15~35 ºC(Low temperature needs to add antifreeze) |

| Working Environment Humidity | Working Environment Humidity |

| Suggested Welding Thickness | less than 4mm (depends on the thickness and materials) |

| Welding gap requirement | ≤1.6mm |

| Working Voltage | 220V/380V 50Hz |

| Weight | 150 KG |

| Size | 90*75*45cm |

Handheld Laser Welding Machine Welding Data:

(This data is for reference only, please refer to the actual data of the proofing; 1000W laser welding equipment can be adjusted to 500W.)

| Power | Stainless steel | Carbon steel | Galvanized plate |

| 500W | 0.5-0.8mm | 0.5-0.8mm | 0.5-0.8mm |

| 800W | 0.5-1.2mm | 0.5-1.2mm | 0.5-1.0mm |

| 1000W | 0.5-1.5mm | 0.5-1.5mm | 0.5-1.2mm |

| 2000W | 0.5-3mm | 0.5-3mm | 0.5-2.5mm |

We support ship by air and sea.

Will pack laser welding machine with foam and dust film first, then pack it with woodon box.

Shenzhen Herolaser Equipment was established in 2004, is a national high-tech enterprise in China, engaged in the

research and development, production and marketing of laser equipment group of companies, has formed a complete series of

industrial laser equipment supply platform.With a team of professional technical personnel,rich management experience, clear development direction to ensure our rapid growth

in the rapid development of the laser industry,we have established branches in Jiangsu, Zhejiang,Shandong, Chongqing and other

regions in China, and we have exported to 60 countries and have overseas agents in 10 countries. Our main products is Laser

Cleaning Machine / Laser Marking Machine / Laser Welding Machine / Laser Cutting Machine.Products are widely used in electrical appliances, mobile communications, hardware products, tool accessories, precision

equipment, jewelry, glasses and watches, integrated circuits, craft gifts, plastic molds, medical equipment and other industries.CertificationsFAQ

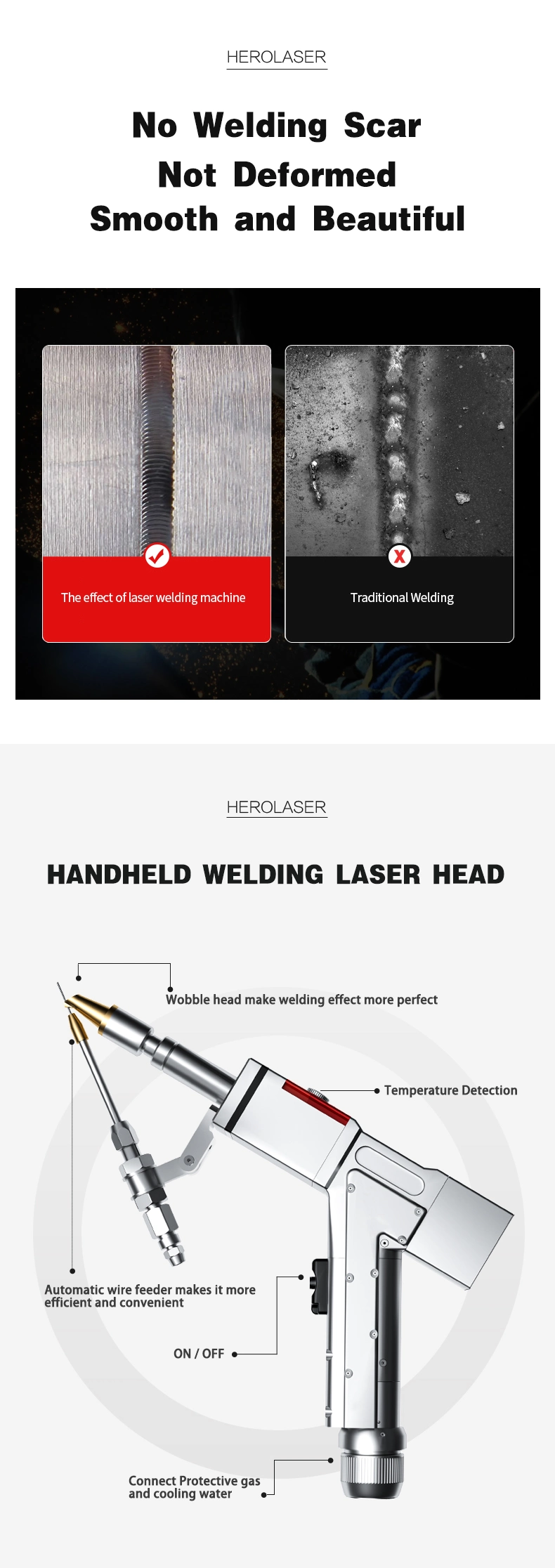

Q:What are the advantages of laser welding machine compared with traditional welding?

A:Small deformation, beautiful welding, fast speed, maintenance free, grinding saving and quick operation.

Q:What materials can be welded by laser welding?A:Stainless steel, carbon steel, galvanized sheet, aluminum alloy, copper alloys.

Q:How long can the laser work?A:In theory, the laser can work for 100000 hours.Q:What are the components of the platform machine?A:The machine is mainly composed of laser source, water tank, welding head and working platform. It can also be equipped with rotating shaft.

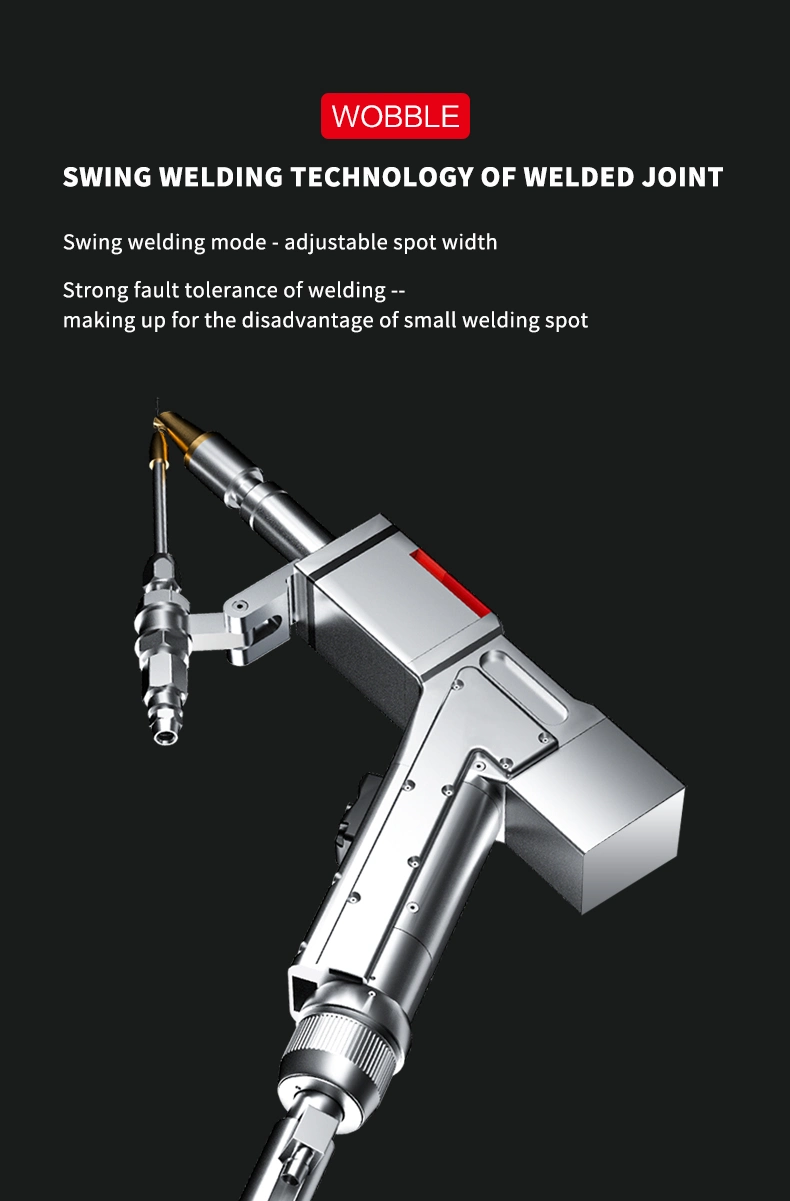

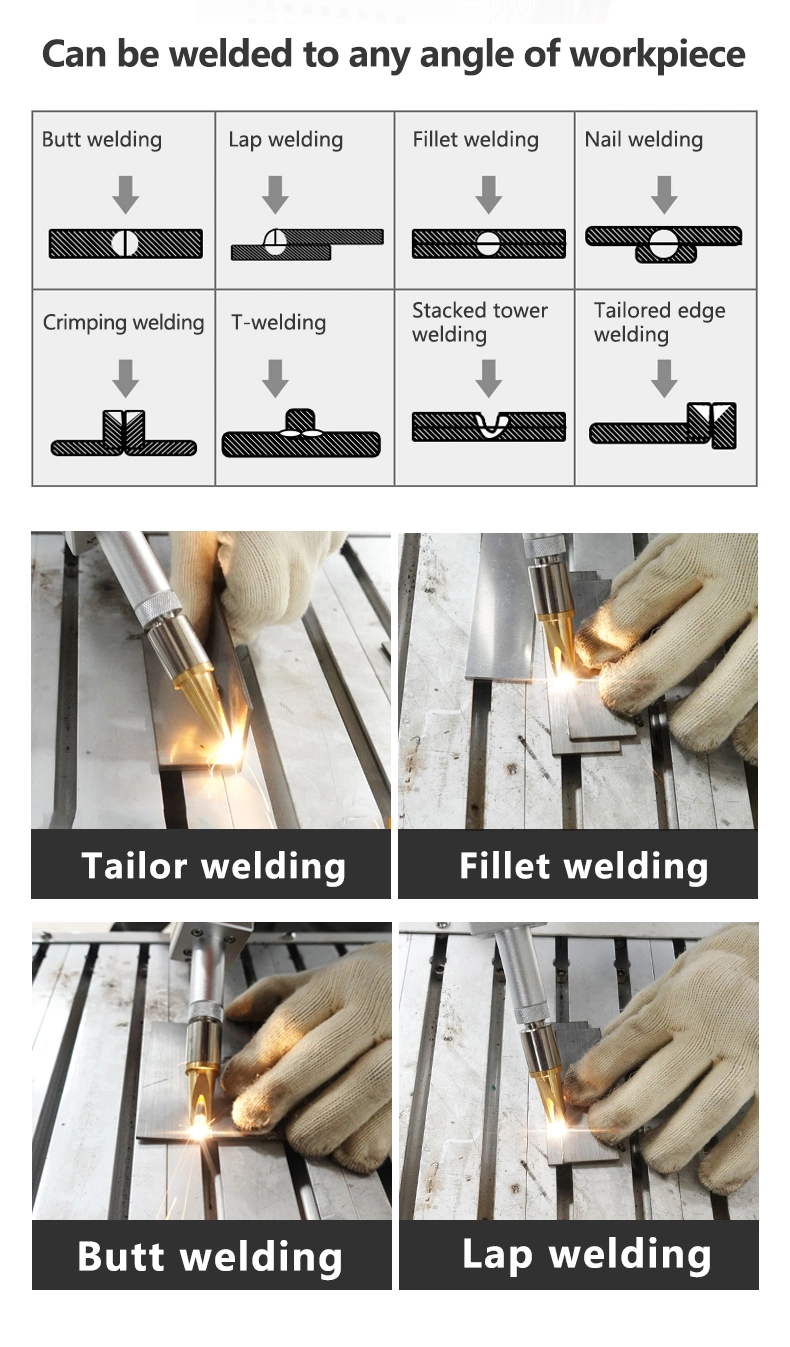

Q:What are the common welding methods, working environment temperature and optical fiber length?A:There are tailor welding, fillet welding, stitch welding and lap welding. It is easy to weld beautifully. The working environment temperature is 15-35 degrees. The fiber length is 10 as standard and can support 15m.